How to survive working in a desk seat

Come on, most of us are working in our chair today! We can ignore the fact that the vast majority of people have opted for

Come on, most of us are working in our chair today! We can ignore the fact that the vast majority of people have opted for

During the inspection of ITM, inspectors are looking into the way the employer comply with the legislation, according to the activity. Regarding the inspections of

Health and Safety and Emergency Situations domains are considered and treated, for now, as less important services, sometimes even useless. Their importance is clarified in

PRAM is the verification of the grounding outlets and the lightning rod. Usually, this verification must be done annual, and its purpose is to prevent

Following the growth of the safety level and the improvement of the working circumstances the European Agency for Health and Safety published a report presenting

Starting with November 2015, the businesses functioning without the fire security clearance are obliged to obtain this document otherwise are risking the sealing of the

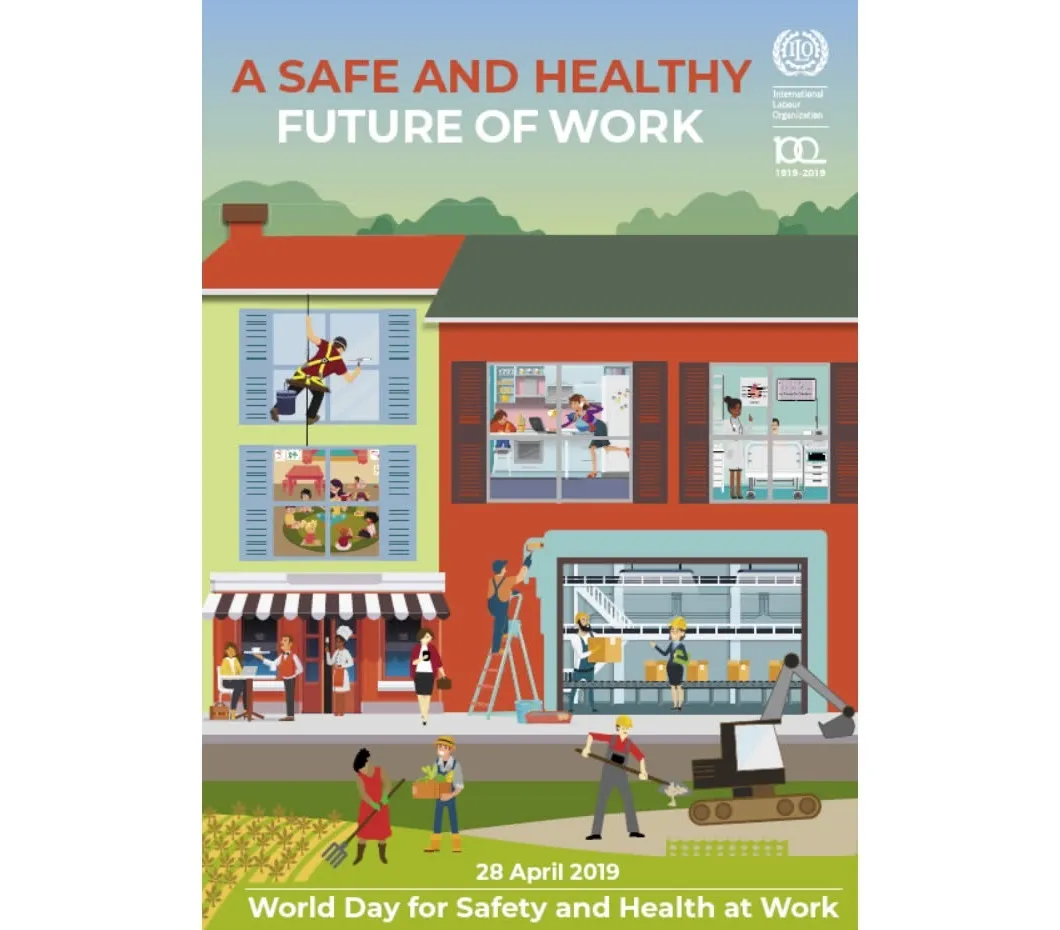

The event is organized by the International Labor Organization and reminds us how important the actions to prevent accidents and occupational diseases worldwide are. In

According to Decision No 1028/2006 concerning the minimum work safety and health requirements relating to the use of screen display equipment, there is a minimum

Emergencies usually happen when you least expect it. Where you are or when such an event occurs is irrelevant, as it can occur anywhere and